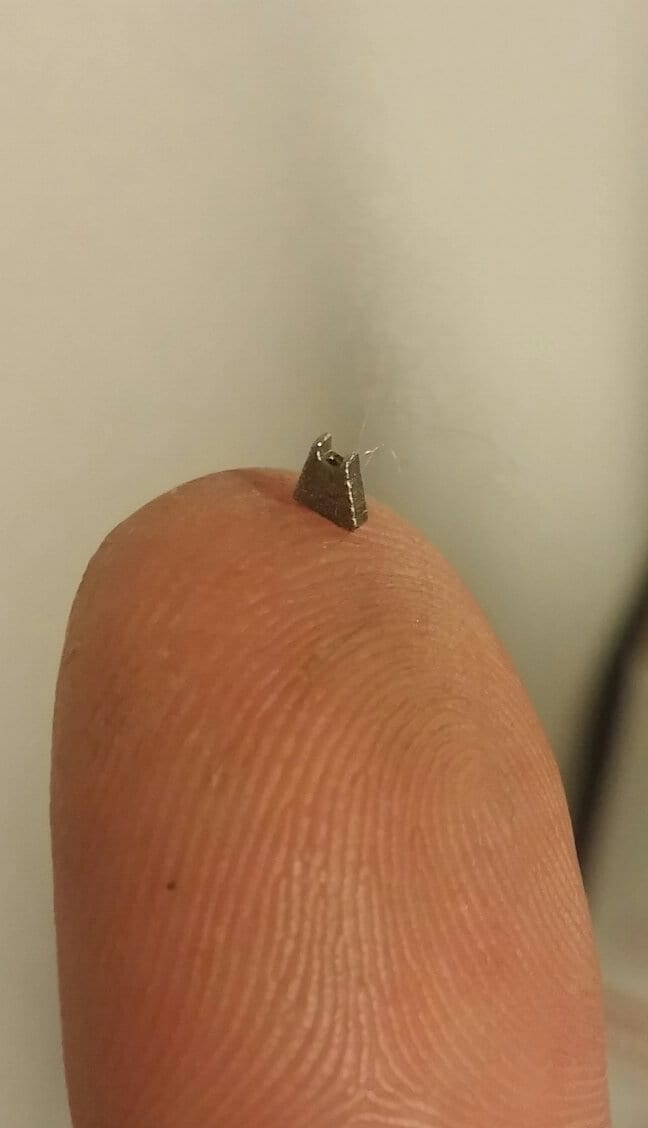

Just How Small Can DMLS Print?

3D metal printing is in its element when it comes to production parts at micro scales. While machine development is focusing on creating DMLS paltforms that can print parts over 14″, Direct Metal Laser Sintering (DMLS), current DMLS capabilities are perfect for small, complex parts. 3D printing enables i3D MFG™ to deliver integral tiny, complex parts in Aluminum, Titanium, Maraging Steel, Stainless Steel and Inconel to Aerospace, Prosthetics, Medical Devise, UAV/UAS, Rocket/Spacecraft, Oil & Gas, Firearms, and Recreational Gear industries. For the part shown, a .015″ (15 thousandths of an inch) high latticed geometry was grown in Maraging (tool) steel. Machining the tiny part out of such a tough metal was expensive and problematic. Since DMLS build parts from mirco powder layers, laser melted together one micro layer at a time, 3D printing precise micro geometries is not much more difficult than printing large bulky parts – in fact, the larger the mass on a DMLS machine, the greater the risk of delamination and failed builds.

DMLS Micro Parts in Production Quantities

Currently, DMLS can accurately and repeatably manufacture parts as small as .030″ in Aluminum and Inconel and .015″ in Stainless Steel, Maraging Steel and Titanium. Additionally, complex assemblies of small to medium-sized parts can be printed as a single part, eliminating weld lines, gaskets and fasteners. With micro parts, this can be a huge savings in precision assembly labor. Combine that with a cost effective means of manufacturing small, complex parts in ferrous and non-ferrous metals ranging from Aluminum that does not register on the HRC scale to Maraging Steel that can be heat treated to 54 HRC, and the design innovations are astounding. Exotic metals also become affordable because DMLS does not produce the 30-70% scrap that traditional machining operations might. Contact i3D™ to learn more about our DMLS, Wire EDM, 3D Scanning and Design-for-3D serv