News: GE Opens $40 million Center For Additive Technology Advancement

GE Opens $40 million Center For Additive Technology Advancement

With all of the big names getting the attention in 3D printing, many are surprised to learn that GE (General Electric) is also a big player. GE is pretty cautious when it comes to large investments in technology as they have seen trends come and go, however, their $40 million investment this past week in a facility for Additive Technology (3D printing) confirms that they see the writing on the wall: Additive Manufacturing is not a fad or trend, it’s here to stay.

One really exciting thing that will come to fruition is the fact that GE never opens a facility just for the sake of using a technology; they will advance it further and that’s really why this announcement is such a big deal. GE opened the new center in Pittsburgh which was exciting to the city because it puts them on the map as a leader in 3D printing and the advancements that come from it.

“We’ve tapped into America’s best-kept secret,” says Jennifer Cipolla, who runs CATA, in regards to Pittsburgh, where Tesla and Google have also opened offices.

“We think Pittsburgh has the chance to be one of the four or five destinations for advanced manufacturing,” adds GE Chief Executive Officer Jeff Immelt.

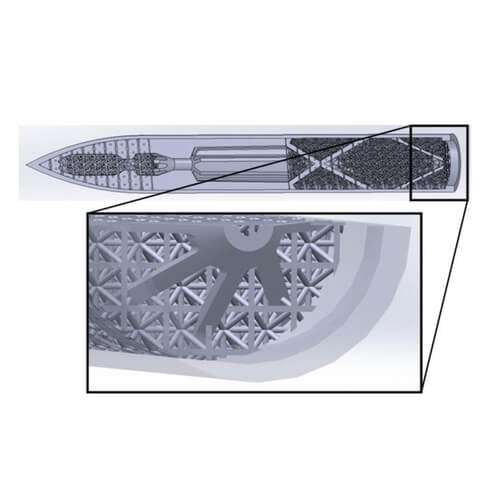

The new facility is funded by each of the GE businesses, with the goal of integrating 3D printing for all. GE has historically been very involved with 3D printing to create fuel nozzles for jet engines.

“Our mission is to ensure additive technology becomes a standard part of the tool kit for each business,” Cipolla says. “By having a shared facility, they can share the cost burden and we can advance the technology across the entire company much more rapidly than if they were to invest individually.”

The goal is to push the limits of additive manufacturing and stay at the forefront of innovation within the industry. The CATA industrialization lab is meant to promote this mission, allowing GE businesses to bring in their 3D printing concepts and optimize them, as well as working to bring them to fruition.

If there was any doubt about the future of additive manufacturing and DMLS, then this move by GE should cement the fact that it’s not only here to stay but it’s going to become the standard in metal printing.