Air Force Institute Of Technology Unveils New 3D Printer

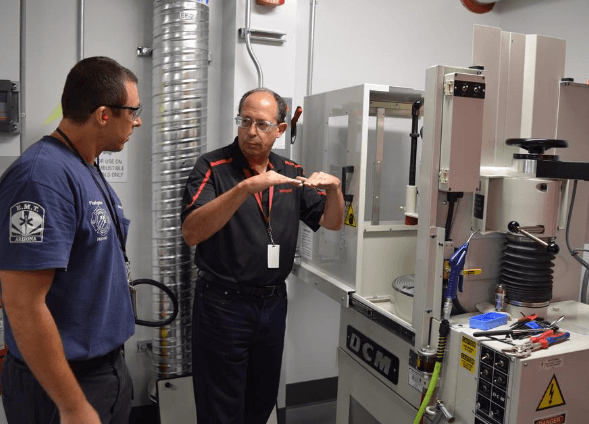

The Air Force Institute of Technology (AFIT) has been using additive manufacturing to build prototypes with polymers for quite a long time, so it seems fitting that they would unveil a new metal additive manufacturing system of their own.

The system that AFIT designed enables them to digitally fabricate aerospace metal parts and is called the Concept Laser M2 3D Metal Printer system.

The entire metal printing process that they have developed is fairly automated from start to finish, including the “sieving” at the end, where as other systems need a lot more manual user handling in order to complete the process.

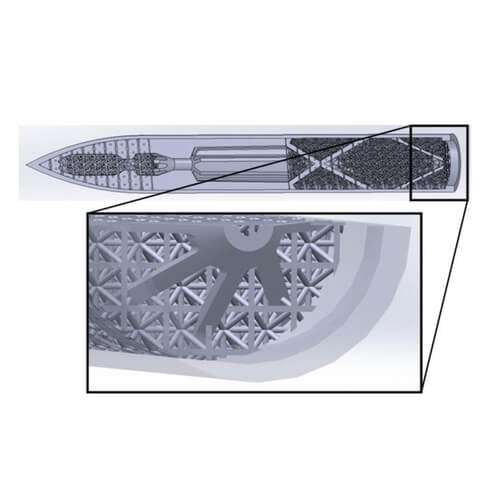

AFTIT’s system will focus on advancing three primary aerospace metals: inconel, titanium, and aluminum. AFTIT is embarking on this endeavor so they can become experts in aerospace metal printing and inform the Air Force on the practical implementation of metal additive components for flight-critical air and space applications.

Maj. Ryan O’Hara, assistant professor, Gradual School of Engineering and Management at AFIT, says,

Ultimately, this is a capability that enhances the defense focused graduate research that we are already doing, whether that is to produce prototypes faster or get someone into the lab for practical experimentation – those are all things we’ve traditionally done in polymers to facilitate research and technology applications, and now we’re applying these techniques with metal

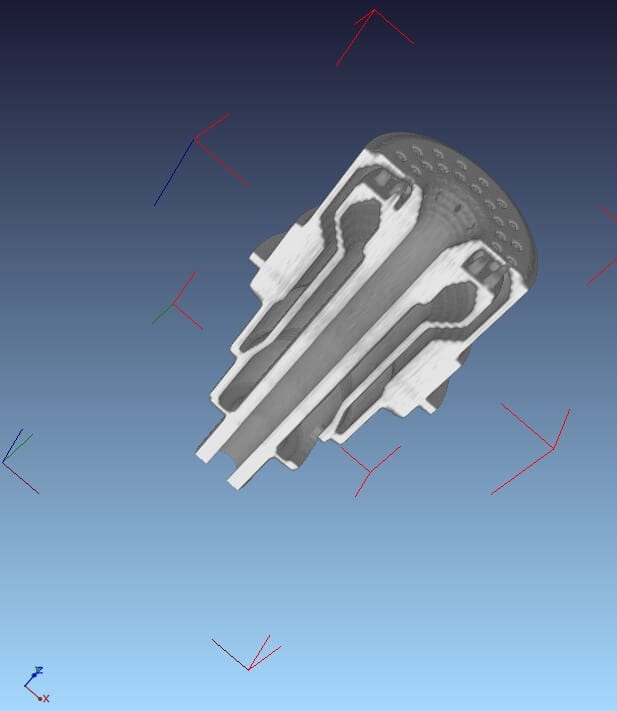

One of the main advantages of the metal additive manufacturing system is that it can produce internal structures to traditional metal parts that could not normally be machined.

There is so much that AFIT can do with additive manufacturing that the possibilities are endless, especially now that they can rapidly print parts they were never able to before at such low cost and speed.