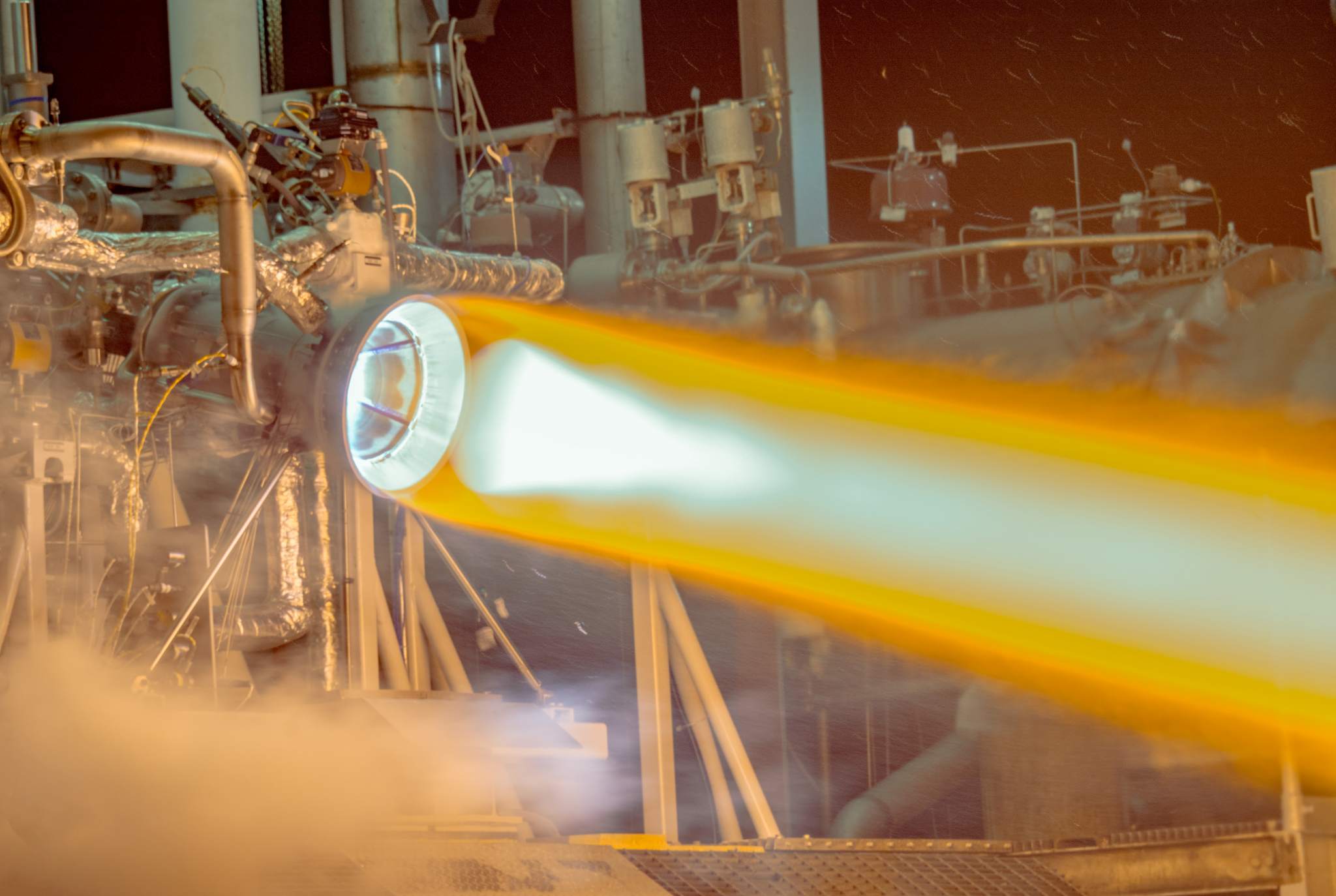

Aerojet Rocketdyne Tests 3D Printed Thrust Chamber With Success

Aerojet Rocketdyne, a California based company, announced that they have successfully completed a hot-fire test of their 3D printed thrust chamber.

After the test, Aerojet Rocketdyne’s Manufacturing Program Manager, Jeff Hynes, said,

“truly transformative as it opens up new design possibilities and paves the way for a new generation of low-cost rocket engines.”

The test and the fact that the thruster was created using 3D metal printing, is truly transformative. The 3D printed copper thrust chamber replaces a series of complex stainless steel tubes which were formerly used. By using 3D printing the company managed to reduce the number of parts in the thrust chamber by 90% to just two components. The design also improves heat transfer within the part, and took only a month to 3D print, saving several months of lead time.

Christine Cooley, Director of the RL10 program, feels that the successful test of the thruster will move the company forward. She suggested that the addition of 3D printing and the need to be more efficient is a result of many factors including growing competition. Several other companies are exploring the use of 3D printed rocket parts and one such company, Rocket Lab, is looking to send a rocket with a 3D printed engine to the moon.