I3DMFG Contributes To Industrial CT For Use In Additive Manufacturing

I3DMFG Contributes To Industrial CT For Use In Additive Manufacturing

I3DMFG has been mentioned in an article alongside Delphi Precision Imaging with regards to new part designs that would be impossible with traditional machining methods and require new measurement tools.

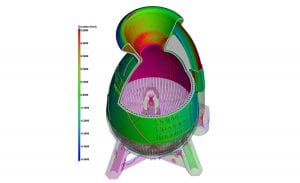

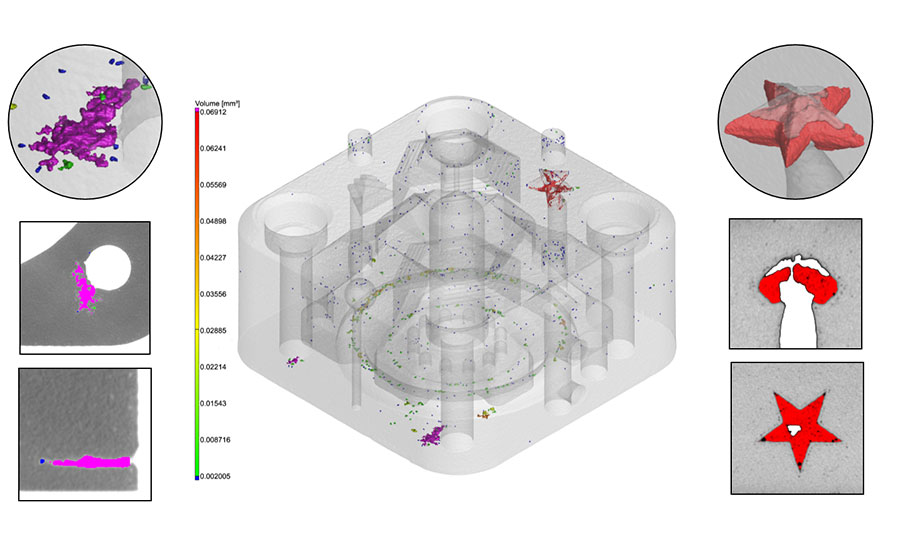

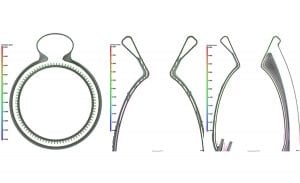

Every day additively manufactured (AM) parts are being used in new applications as the industry rapidly matures. As additive parts become more economical for small productions runs and move beyond use solely in tooling and prototyping, the need to nondestructively inspect parts for quality increases as well.

“Industrial CT is an excellent inspection method for additive parts and components from the automotive, medical implant and aerospace industries where quality and a high degree of reliability are critical,” says Blake Chenevert, president of Delphi Precision Imaging. Computed tomography (CT) has some advantages over other nondestructive inspection methods for additive manufacturing.

There are a lot of challenges currently facing the Additive Manufacturing industry such as defects, parts coming out as intended, yields, and cost/benefits. The article addresses each of these topics head on and in the area of Quality Control Inspection, I3DMFG had this to say,

“As quality requirements evolve inside of a disruptive industry like additive manufacturing, finding tools and innovative approaches to using those tools to advance nondestructive testing methodology is critical,” says Erin Stone, president of I3D MFG, a DLMS printer.