3D Printing Predicted to Produce 50% of Parts & Components

A recently released Gartner study found that 3D printing is not only widely used for rapid prototyping and product development, but that ” it (3D printing) was starting to play a significant role in short run production of finished products.” What evidence does Gartner have to support that prediction? First, they performed a survey of 300 people from a multitude of 100+ employee organizations and 37% of them use end-use quality 3D parts.

The findings showed that, “respondents felt overwhelmingly that using a 3D printer as part of their supply chain generally reduces the cost of existing processes.” According to Gartner’s research, “The mean cost reduction for finished goods is between 4.1 percent and 4.3 percent, which is an impressive figure. It shows that early adopters of the technology are finding clear benefits, which are likely to drive further adoption.”

3D Printed Parts Improve Costs, Supply Chains & Efficiencies

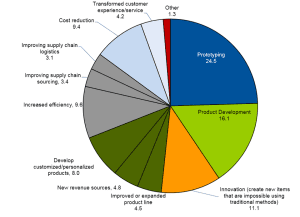

Based on the survey input, Gartner broke out the current 3D printed part function. Cost reduction was over 9% of the decision to use 3D printing in 2013. It only makes sense that this factor will grow as the technology improves in both DMLS and SLS machines. Another interesting statistic based on the break-out above is that less than 50% of the 3D printing is primarily driven by prototyping and product development. This is a drastic shift in the industry that signals that 3D printing is truly a manufacturing option. i3D MFG™ utilizes 3D metal printing to produce end-user parts for Aerospace, UAV, Space, Medical, Prosthetics, Automotive, Firearms, Oil & Gas, Energy, and Recreational Gear industries. Common DMLS metals include Aluminum, Stainless Steel, Titanium, Inconel, and Maraging Steel. i3D MFG™ also creates custom powders and tailors its machines to print these metals for specialty applications. Read about other DMLS applications at https://www.i3dmfg.com/i3d-news-press/.