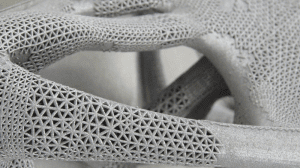

Marc Saunders, Director – Global Solutions Centres at Renishaw, recently discussed how Additive Manufacturing (AM), a specifically 3D metal printing, can give us the ability to create components from designs that would be nearly impossible to produce conventionally.

As he points out, it’s not as simple though as having “unfettered freedom” to do whatever we want. There are capabilities and limitations.

Mr. Saunders does a great job pointing out some key design considerations for laser melted metal parts. Here’s a few he points out:

Mr. Saunders does a great job pointing out some key design considerations for laser melted metal parts. Here’s a few he points out:

- Feature Size

- Surface Finish

- Overhangs

- Lateral holes

- Minimizing supports

- Residual stress and distortion

Give the article a read in order to get the details on these key considerations. As Marc point out,

“AM gives us huge freedom to design parts differently, but we do need to be aware of some of the characteristics and limitations of the process, so that we create parts that can be built successfully.

The DfAM rules described above are not too onerous in practice, and actually encourage us to consider ways to make parts that are lighter, faster to build, and more cost-effective.

Modern design and build preparation software helps enormously to find an optimum design, orientation and support strategy so that we can produce consistent parts economically. “